Tunnel Construction

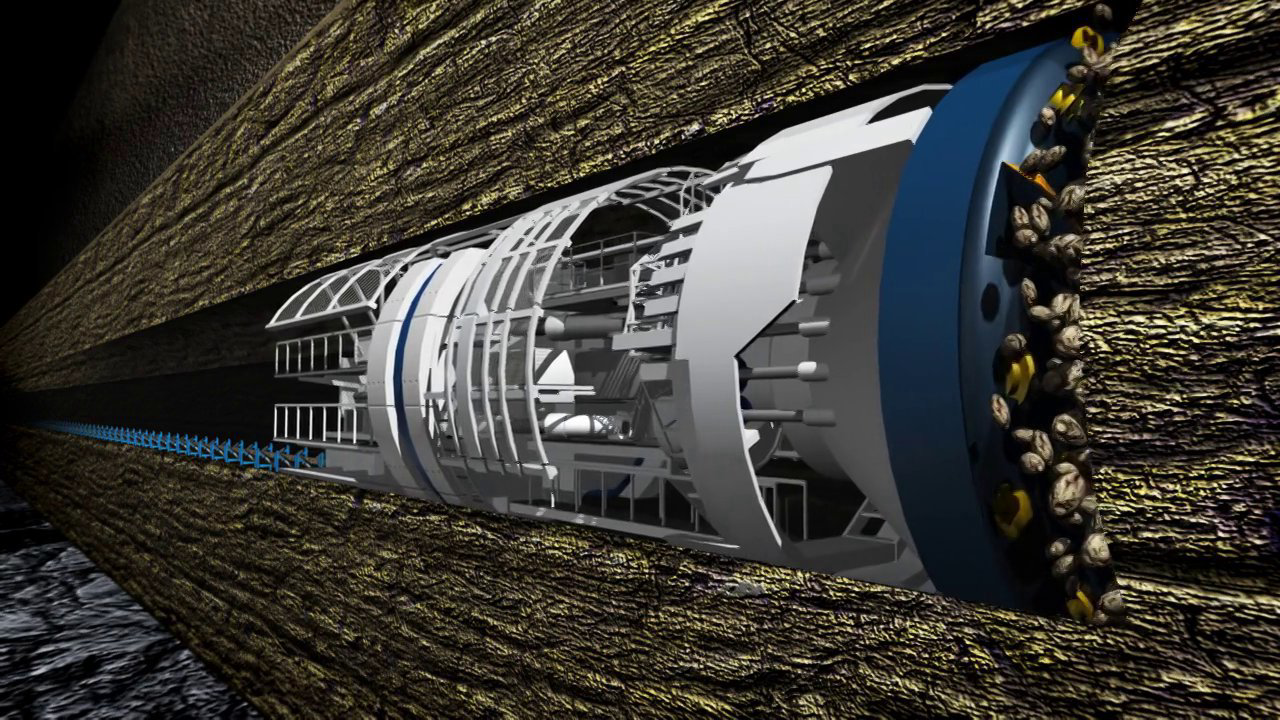

Tunnel Boring Machines are large automated assembly lines that remove earth and rock and install tunnel linings in one continuous and controlled process. These machines have been used successfully in every soil condition around the world, and for 35 years in Massachusetts, with an unparalleled record for safety, predictability, and cost. Automating the process has several advantages. First, progress is faster, safer, more reliable, and less expensive. Second, the tunnel linings are typically precast, under controlled conditions, so quality is well-controlled and the resulting tunnels are watertight. Finally, earth pressure can be maintained in a controlled way preventing damage to structures located above. TBM's operate largely out of sight, with minimal impact on surface activities. Rail links in Zurich, London, Malmo, Leipzig and a host of other cities have been built with this method at very reasonable cost.

Tunnel Boring Machine during construction of the Leipzig City Tunnel Rail Link [photo by Ingbife]

Crossrail TBM [Crossrail]

Station Construction

While the tunnels will be bored by TBM’s, the stations will be built by more conventional methods, either mined (like Porter Square Station), or excavated top-down (like Harvard and Davis Square Stations), as appropriate.

Station designs are still conceptual, but it appears likely the new South Station will be built below Fort Point Channel so as to avoid interference with adjacent buildings. This also provides the opportunity for a harbor view when emerging from the station, a fitting gateway to our waterfront city. The smaller commuter rail-only stations at the Green / Orange Lines and Blue Line, will be built below the Artery tunnel, where direct vertical access is impossible. These stations can be mined via the new rail tunnels, but cost savings can be achieved by coordinating station construction with development of adjacent sites, particularly at the Government Center Garage and Aquarium Garage, where major redevelopments are planned. Such coordination should be beneficial to both the city and the developers and should be actively encouraged.

Protecting the Alignment

Railroads operate with strict geometric requirements that limit the ability to navigate around obstructions. For this reason, it is essential to avoid deep foundations or other structures within the rail corridor. In London, a process called ”safeguarding” is used for just this reason to protect rail alignments during the planning process. No similar protection is in place for the North South Rail Link alignment, and there is a real risk that it could be fatally compromised by planned development at many points, including North Point, Widett Circle and Hook Wharf.

A proposed 21-story Building at Hook Wharf, between Seaport Blvd and Northern Ave bridges, is located directly above the planned NSRL tunnels. The two projects should be coordinated to assure the alignment is not compromised. [Elkus Manfredi Architects]

A portion of the 42 acre North Point site, purchased by Divco West in July 2015, was designated as an ideal staging area for NSRL tunnel construction. Other options still remain, but not many. [The Boston Globe]

These projects need to be coordinated with the rail alignment, and despite the recommendation of the Boston Globe editors in early 2015, no protocol for this has been put in place.

Proposed construction staging area identified in the NSRL DEIR / MIS occupied about half of the recently sold 42 acre parcel. A staging area adjacent to the tunnel portal is needed during the construction period. [VHB/FRH]

The Boston Globe published an editorial March 5, 2015, urging state planners to protect the NSRL alignment from obstructions that might result from uncoordinated development above. [© The Boston Globe]